Engineering change coordination and implementation is one of the most important processes that supports New Product Introduction and Sustaining Engineering. It also happens to be one of the most cross-functional process as it involves and impacts many groups, including design/engineering, purchasing, manufacturing, quality, supply chain planning, logistics, customers and suppliers.

Causes and sources of engineering changes are numerous and the effectiveness of engineering change coordination and implementation can have dramatic impact on NPI speed, product quality, and reliability.

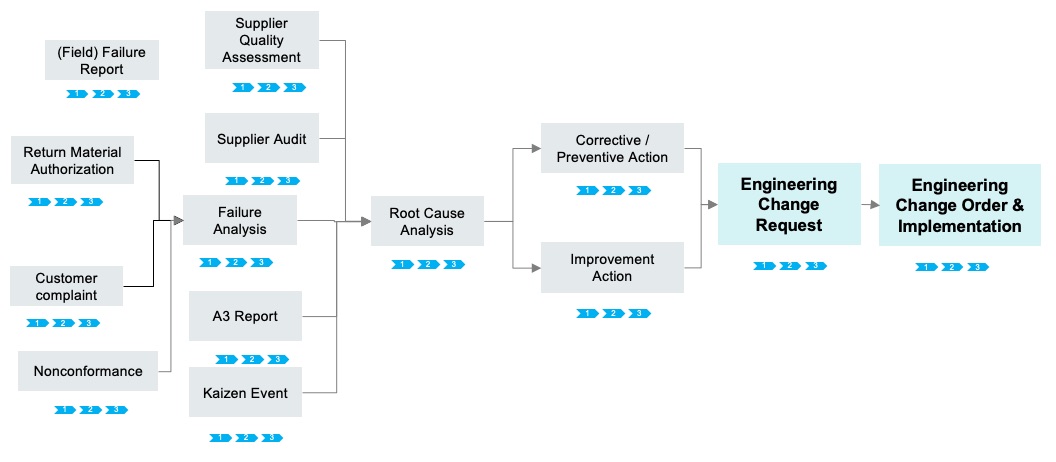

Engineering Changes in the overall scope of product development and quality management

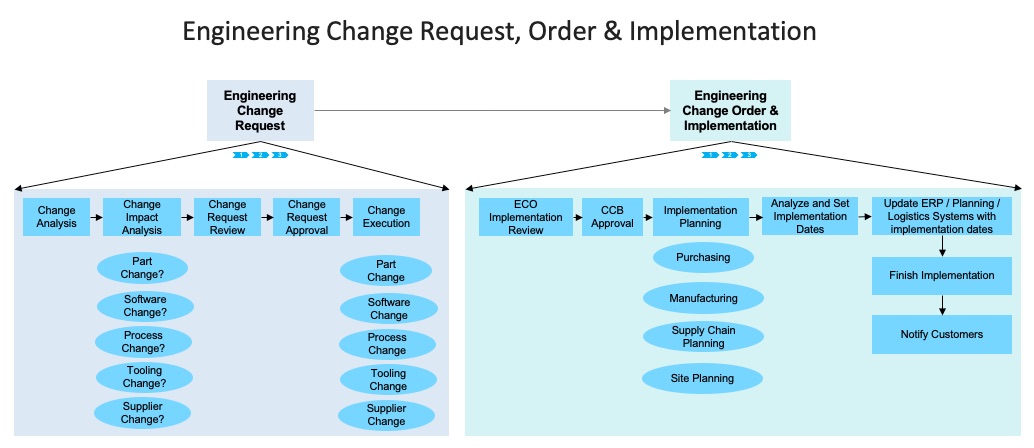

The engineering change request, order and implementation process(es) are themselves highly cross-functional as it involves a number of stakeholders and requires orchestration of activities. A high level engineering change request, order and implementation process may look like this

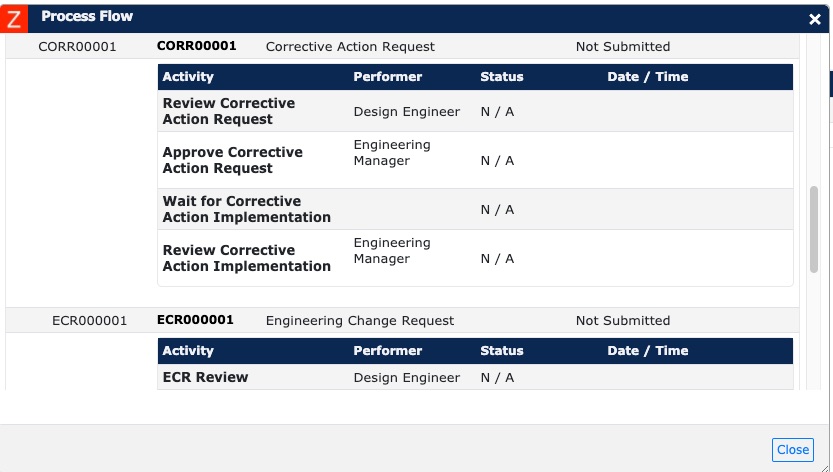

Cogence and ZFlow (since ZFlow works as a workflow and integration layer in Cogence) provide exceptional support for Engineering Change Request and Engineering Change Orders.

ECR and ECO as a continuation of upstream workflows

Engineering Change Requests and Engineering Change Orders can be a result of upstream processes such as Failure Reports and Corrective Actions as connected workflows.

Cross-functional Workflows

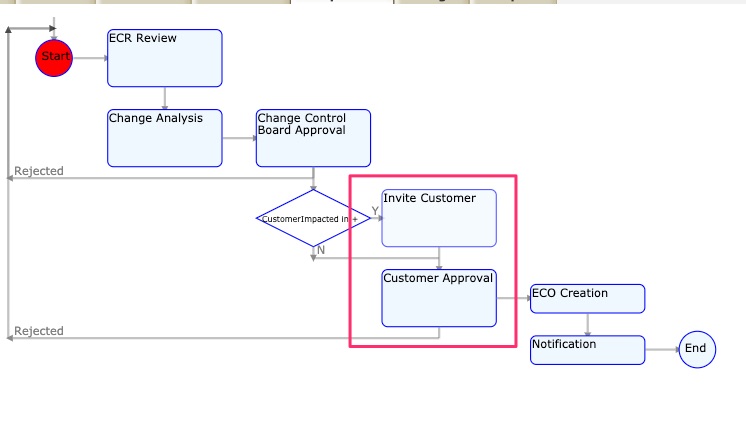

Engineering Change and Order workflows in ZFlow and Cogence are inherently cross-functional and they bring together different stakeholders to do the right activity at the right time (or concurrently).

In the above example you can even see that customers can be involved in approvals for Engineering Change Requests.

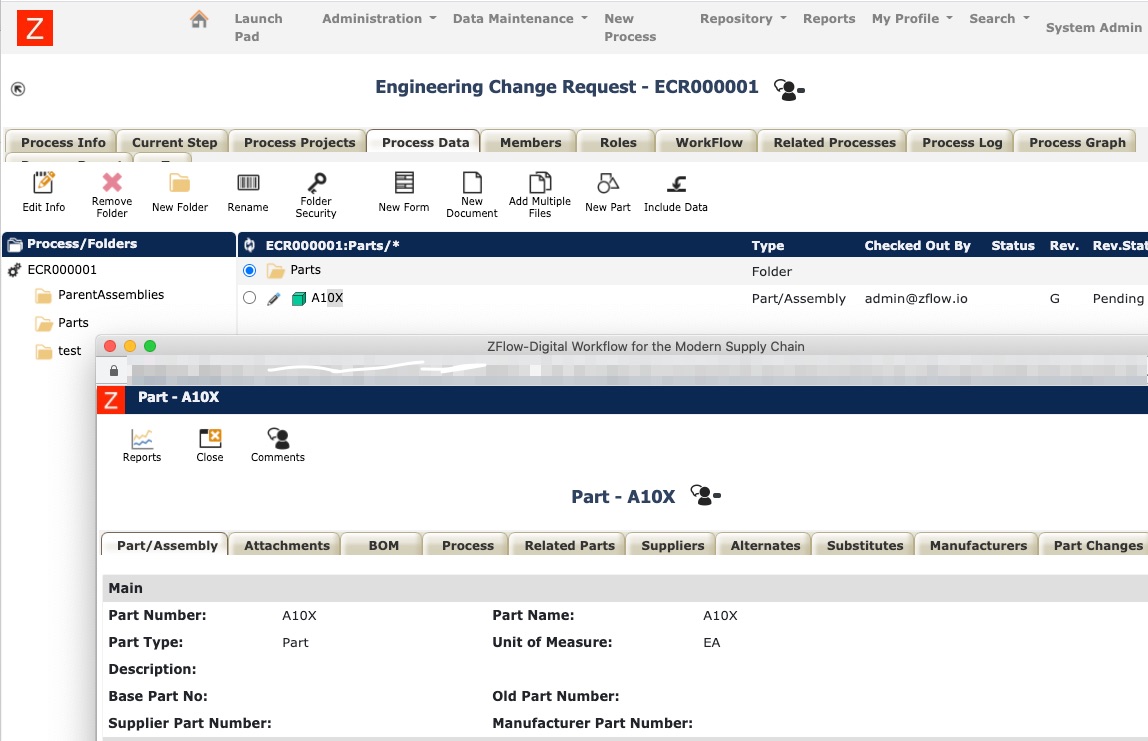

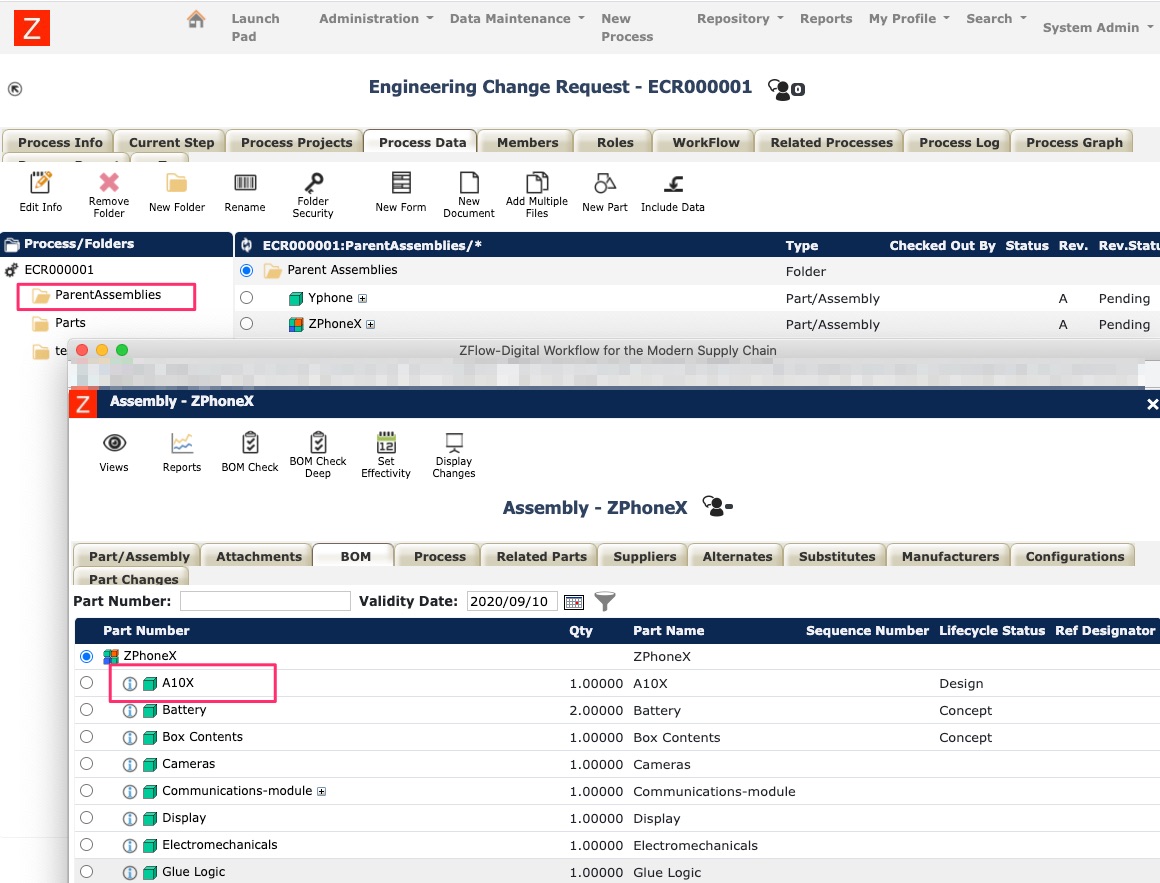

Handling Engineering Change Data (Parts, etc.) Intelligently

Key to a smooth and effective engineering change coordination is ability to handle change related information that is often in interconnected and rich such as parts, drawings, process plans, etc.

Parts that may be impacted because they have the part that is being changed as a component

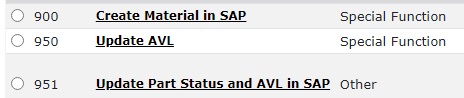

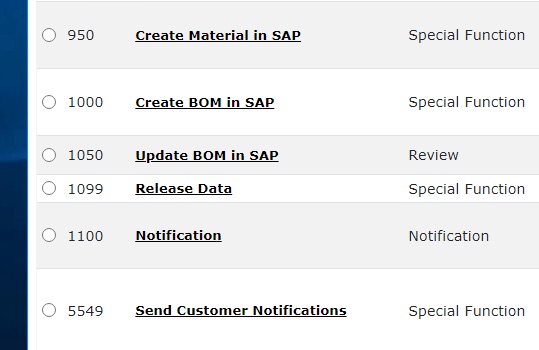

Integrating to downstream systems (ERP, Planning, Manufacturing, Customer Facing Systems)

Engineering change and related processes tend to impact many stakeholders and as a result need to integrate with many systems (ERP, Supply Chain Planing, Commerce, Customer Service, Logistics, etc.) so that they are properly implemented and propagated. This is one of the most challenging aspects and historically proven to be the most difficult to accomplish due to the isolated nature of technology applications that support various functions.

We overcome this difficulty due to exceptional support for application integration in ZFlow. Seamless integration to relevant applications is part of the engineering change processes as shown below

Creating/updating Vendors